109

The fan packages shall be factory assembled complete with electric heat/hot water coils. Factory mounted

control panel shall provide all internal control and fan power wiring for a single point field connection. An

optional factory mounted disconnect switch shall be furnished and prewired so as to disconnect all electrical

components in the fan package. A single point field connection will be made at the disconnect switch. Fan

package must be labeled and listed by a nationally recognized and locally accepted testing laboratory, such

as ITS Intertek testing services. Fan packages must be tested for safety and in accordance with the latest

National Electric Code. Casing shall be a minimum of 20 gauge galvanized steel and acoustically insulated

with 1” fiberglass. The casing shall be Listed and meet NFPA 90A and 90 requirements. Blower casing

shall be constructed of heavy gauge steel and baked enamel finish. Fan wheel shall be forward curved

centrifugal type, dynamically balanced and be driven by direct drive, single speed permanent split capacitor

motors. Motors shall be single phase, 1050 RPM. An electronic motor speed control shall be provided to

allow continuously adjustable fan speed from minimum to maximum. Fan assembly shall be mounted on a

16 gauge steel sub-base, but shall be internally isolated with rubber-in-shear isolators to prevent vibration

transfer to the sub-base. Motors shall also be isolated with rubber-in-shear isolators between the motor

mounting legs and the blower casing. Fan motor assembly shall be accessible through access panels from

both sides and rear of cabinet (bottom and top access panels are not acceptable). Access panels shall have

gasket to prevent leakage and vibration transmission. An electric heater (hot water optional) shall be part

of the total listed package and shall be controlled by pneumatic, electric controls enclosed in a NEMA-1

enclosure on the side of the cabinet. The panel shall be gasket sealed to prevent air leakage. Heater shall

be the requested available voltage and phase. Each fan package will be factory tested prior to shipment

and certified as such. Each fan shall have an optional throw-away or permanent filter, and an optional

acoustically lined discharge plenum or return air boot.

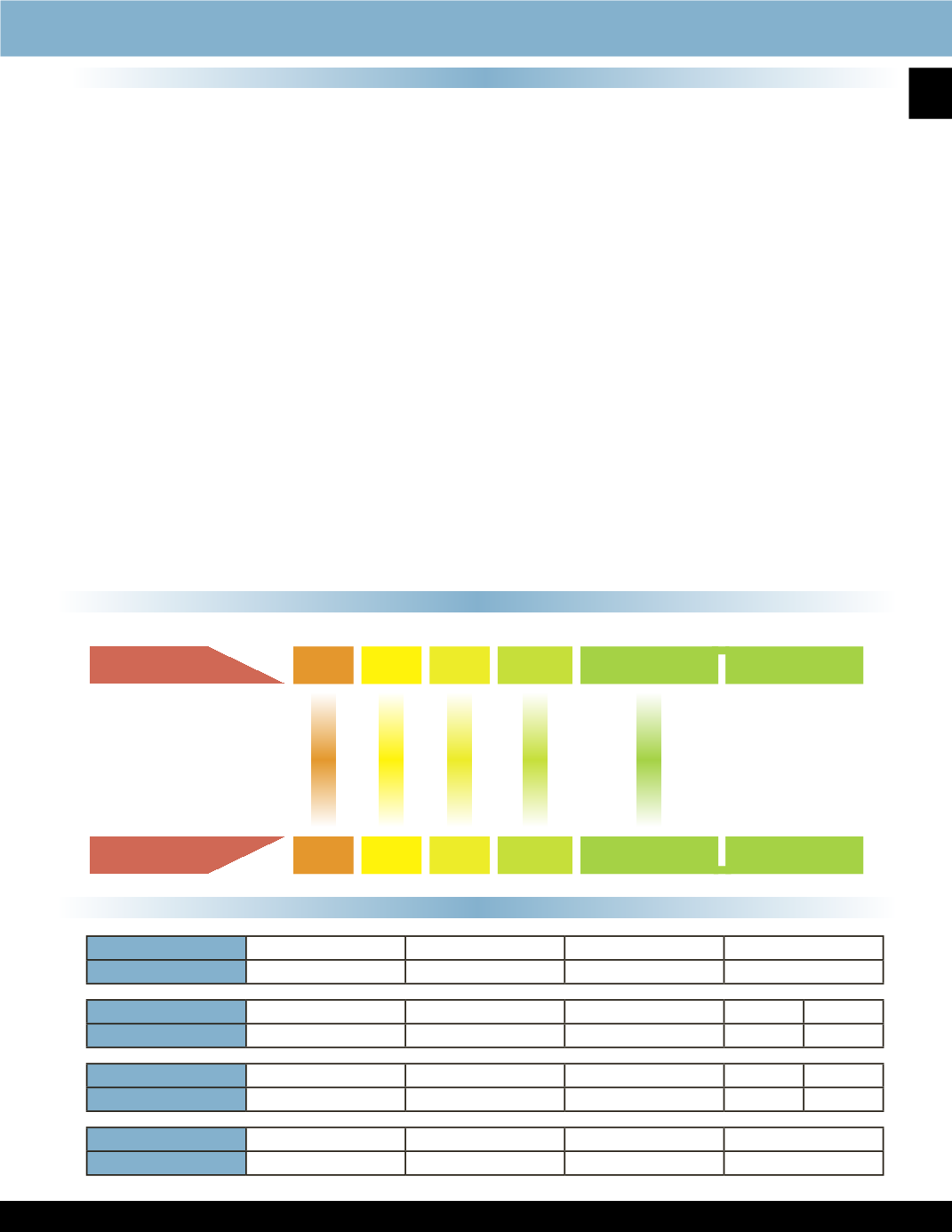

Custom Specified Models

Minimum CFM’S Based On KW

Product Specifications

KW

5

7

9

10

CFM

400

500

600

700

KW

11

13

14

15

17

CFM

800

900

1000

1100

1200

KW

18

20

21

23

24

CFM

1300

1400

1500

1600

1700

KW

26

27

28.5

30

CFM

1800

1900

2000

2100

HOW TO DESIGNATE A MODEL:

Electric Heat

Hot Water Heat

RFH

RFH

E

W

500

500

5 KW

12.6 MBH

Disconnect Switch Washable Filter

Inlet Attenuator

Totally

Enclosed Motor

SERIES

HEAT TYPE

SIZE

HEAT CAPACITY

OPTIONS

RFH Series Fan Coil Units